In the graphic arts sector, every stage of the production process has a significant impact on the final result. Among these stages, prepress is one of the most crucial, as it defines the quality and precision with which designs will be reproduced on different substrates. Today, one of the technologies that has revolutionized this phase is the CTP (Computer to Plate) system, which has replaced traditional prepress techniques and allowed companies like SG Colmar to reach new levels of quality and efficiency.

CTP, also known as Computer to Plate, is a system that allows digital designs to be transferred directly to printing plates without the need for intermediate films, representing a significant leap over previous methods. By avoiding analog processes, this technology not only improves print quality but also optimizes production time and reduces the risk of errors. Below, we will explore in detail what CTP is, its advantages, and how it has transformed the graphic arts environment at SG Colmar.

What is CTP and how does it work?

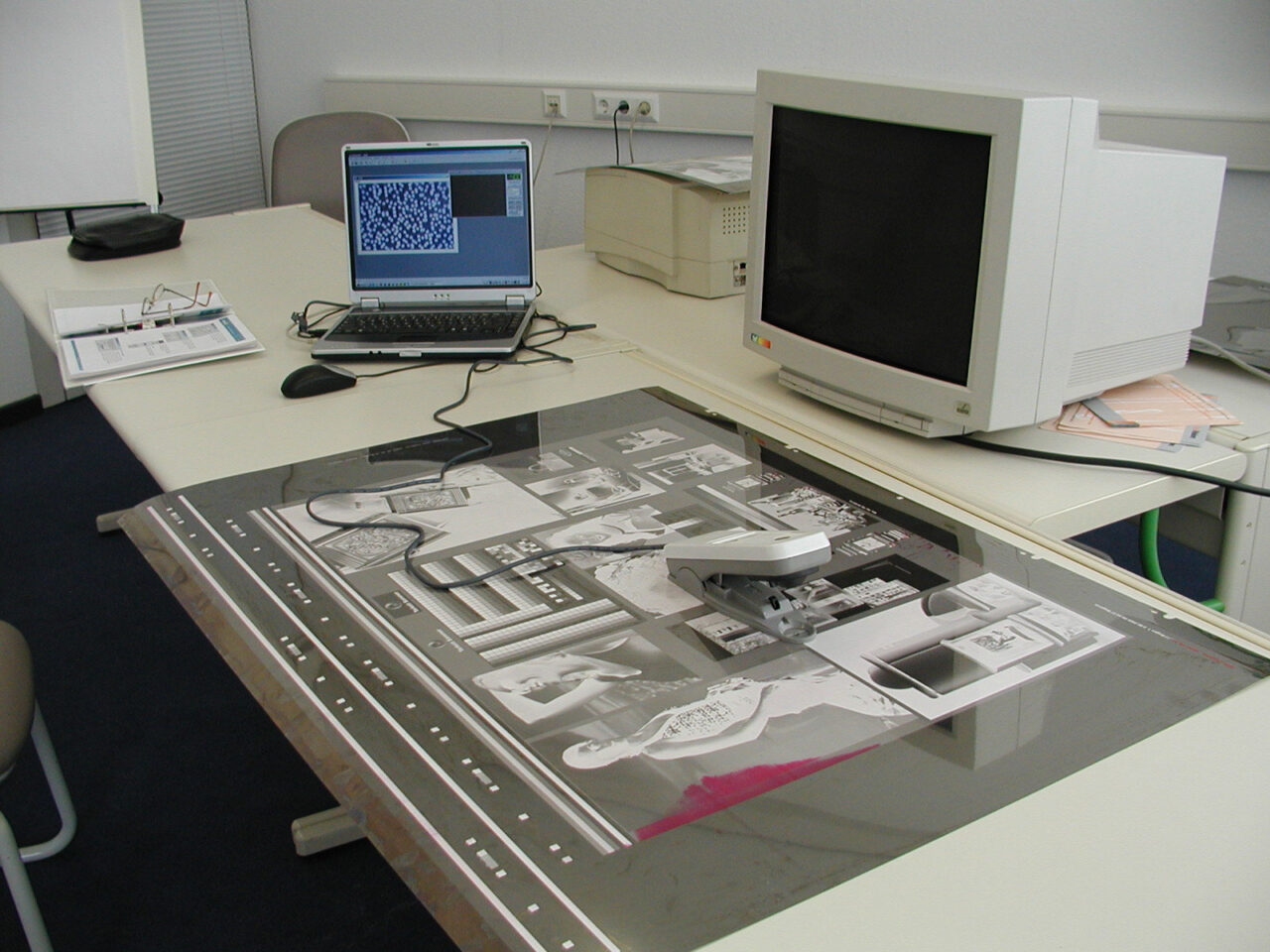

CTP is a digital printing system responsible for engraving printing plates using high-precision lasers. Instead of creating a film of the design and then manually transferring it to the plate, CTP directly engraves the plate from the digital file. This process is faster and more accurate, allowing printers to obtain much more consistent results.

At SG Colmar, we use state-of-the-art CTP equipment that allows full control over every detail of the design, from line definition to exact color reproduction. This translates into superior print quality, as registration errors and exposure issues common in previous methods are eliminated. Additionally, the use of CTP allows for quick adjustments, such as last-minute design changes, without needing to repeat the entire prepress process, significantly improving production flexibility and responsiveness.

Advantages of CTP for Prepress

The advantages of this technology are multiple and extend to different aspects of the production process. The main ones include:

1. Greater precision and print quality:

CTP allows printing plates to be engraved with millimeter precision, eliminating common errors in traditional systems such as distortions or color misalignments. At SG Colmar, this translates into sharper, more defined prints with vibrant and uniform colors. By not depending on films, loss of detail is avoided, achieving an exact reproduction of every line and shade.

2. Reduction in production times:

The prepress process with CTP is much faster than the traditional one, as it eliminates intermediate steps like film creation and assembly. This means projects can be ready in less time, allowing tight deadlines to be met without sacrificing quality. At SG Colmar, we have significantly reduced delivery times thanks to the implementation of this technology, allowing us to respond more agilely to our clients’ needs.

3. Lower margin of error:

Being a fully digital process, CTP minimizes registration and exposure errors that were common with films. Furthermore, it allows for easy and quick last-minute adjustments, ensuring the final design is printed exactly as conceived. This correction capability is especially useful in complex projects, where even the smallest error can have a major impact on the final result.

4. Optimization of production costs:

Although the initial investment in CTP equipment is high, in the long run, this technology proves much more cost-effective. Costs associated with films, chemicals, and additional labor are eliminated, and by reducing production time, resources are also optimized. For companies like SG Colmar, this translates into greater efficiency and the ability to offer competitive prices to our clients without compromising quality.

5. Sustainability and lower environmental impact:

By not using chemicals or films, CTP is a more environmentally friendly alternative. Digital technology reduces the use of polluting materials and generates less waste, helping companies comply with environmental regulations and promote more sustainable production practices. At SG Colmar, we are committed to sustainability, and the use of CTP is one of the ways we contribute to reducing the environmental impact of our operations.

Implementation of CTP at SG Colmar

At SG Colmar, the adoption of CTP technology has been a natural step in our strategy to offer clients the highest quality printing solutions. We have integrated this technology into our prepress workflow, allowing us to control every aspect of the process and guarantee optimal results for every project. Furthermore, the use of CTP has allowed us to offer a wider variety of finishes and personalized solutions, adapting to the specific needs of each client.

Whether in the production of catalogs, brochures, or more complex projects like packaging design, CTP allows us to maintain a consistent and precise level of quality. Our clients trust us not only for our experience but also for our ability to use the most advanced technology to take their ideas to the next level. The flexibility and precision that CTP brings to our production allows us to tackle projects of any size, ensuring that every detail is captured exactly as planned.

If you would like to know more about how we implement CTP technology in our prepress services or need help with your next graphic project, get in touch with us using the following form. Our team of professionals will be happy to advise you and offer the solution that best suits your needs.